The Prominence of China CNC Machining Parts Factory in Modern Manufacturing

In today’s fast-paced industrial environment, precision and efficiency are paramount. Among the many contributors to the global manufacturing ecosystem, China CNC machining parts factories stand out for their innovative approaches and unmatched production capabilities. With a commitment to quality and advanced technology, these factories have transformed how industries approach parts manufacturing, making them vital partners in various sectors.

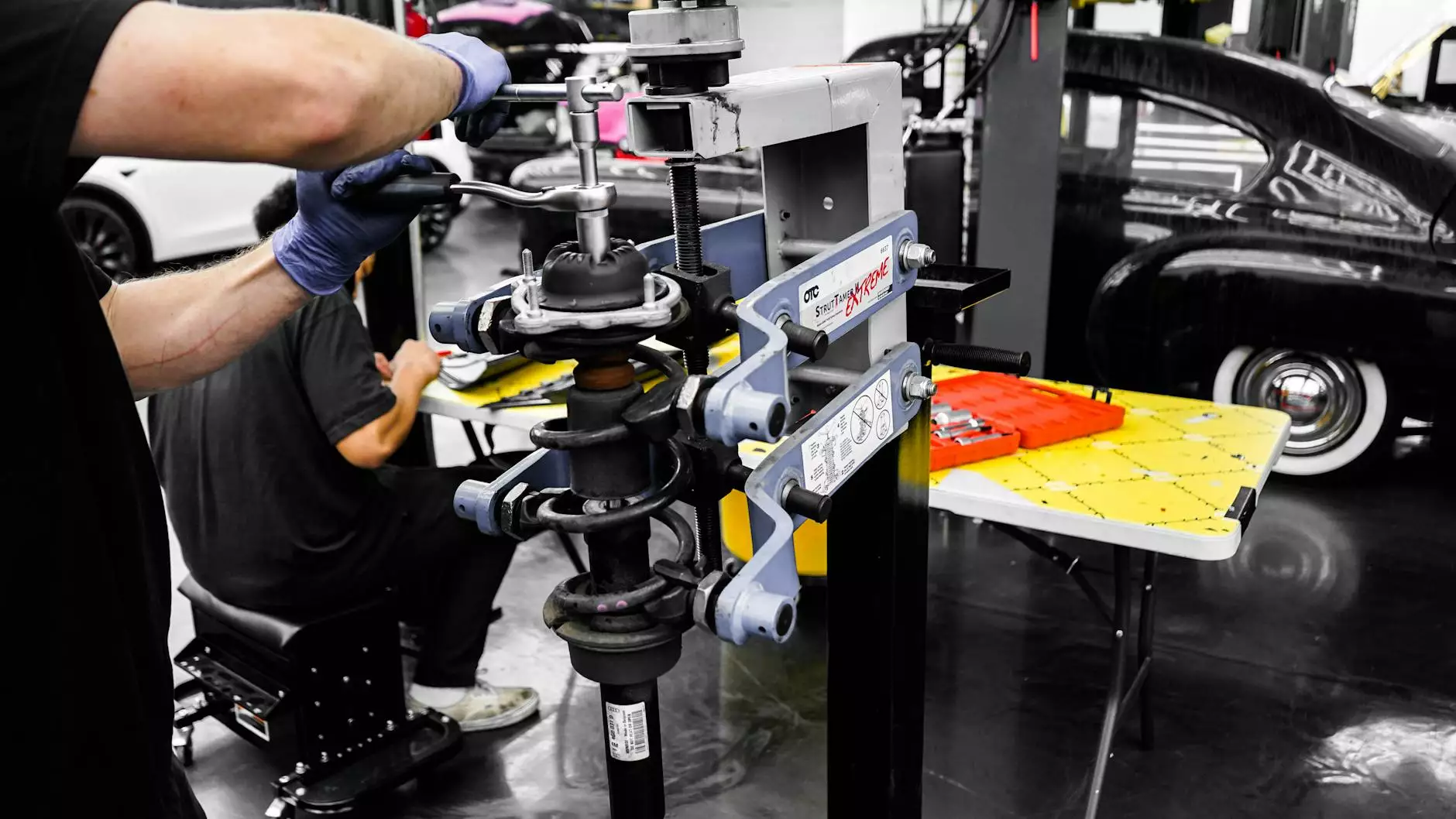

Understanding CNC Machining

CNC (Computer Numerical Control) machining is a technology that employs computerized controls to operate machine tools. This engineering process is pivotal in producing intricate parts with high precision.

What Makes CNC Machining Essential

- Precision: CNC machines can produce components with an accuracy of up to ±0.005 mm, which is crucial for industries where precision is critical.

- Efficiency: Once programmed, CNC machines can operate continuously, producing identical parts in large quantities with minimal downtime.

- Complexity: CNC machining allows for the production of complex shapes that would be difficult or impossible to achieve with manual machinery.

- Automation: Automation reduces labor costs and human error, enhancing the production process's overall reliability and speed.

The Role of China in CNC Machining

China has become synonymous with manufacturing, and the China CNC machining parts factory is at the forefront of this transformation. With a unique blend of skilled labor, cutting-edge technology, and competitive pricing, these factories have carved out a leading position in the global manufacturing supply chain.

The Advantages of Sourcing from China CNC Machining Parts Factories

When companies choose to source their CNC machining parts from China, they tap into a wide array of benefits that can significantly enhance their operations:

1. Cost Efficiency

One of the most compelling reasons companies turn to China CNC machining parts factories is the cost savings. Labor costs in China are generally lower than in Western countries, leading to reduced manufacturing costs.

2. Advanced Technology

Chinese manufacturers are quick to adopt the latest machining technology, ensuring high precision and quality. Factories incorporate state-of-the-art CNC machines, enabling them to meet rigorous international standards.

3. Scalable Production

Whether a company needs a small batch of specialized parts or a large volume of products, China CNC machining parts factories can scale operations effectively to accommodate varying production needs without compromising quality.

4. Quick Turnaround Times

Rapid production capabilities mean that clients can receive their components faster than traditional methods allow. This efficiency enables businesses to respond promptly to market demands and changes.

5. Diverse Manufacturing Capabilities

Factories in China are not limited to one type of material or process. From metals to plastics, and from prototypes to full production, the variety of options available can cater to almost any manufacturing need.

The Impact of Quality Standards

Quality is non-negotiable in manufacturing. China CNC machining parts factories emphasize strict adherence to international quality standards. Many factories hold certifications such as ISO 9001, which ensures that they meet high standards of quality management systems. This commitment to quality not only enhances the reputation of these factories but also instills confidence in international clients.

Ensuring Quality in CNC Machining

To maintain high-quality standards, Chinese factories implement the following practices:

- Quality Control Systems: Comprehensive quality checks during various production stages ensure that any defects are identified and rectified promptly.

- Employee Training: Skilled operators undergo regular training to keep them updated on best practices and new technologies.

- Material Sourcing: Factories procure high-grade materials, which is fundamental to producing durable and reliable parts.

Challenges and Considerations

Despite the many advantages of partnering with China CNC machining parts factories, businesses must also consider potential challenges when outsourcing their manufacturing needs:

1. Communication Barriers

Language differences can sometimes lead to misunderstandings. It is crucial to establish clear communication channels and maybe even hire translators if necessary.

2. Time Zone Differences

Working across time zones can pose challenges in terms of coordination. Companies can mitigate this by having set schedules for meetings and updates.

3. Shipping and Logistics

International shipping can introduce delays. Businesses must plan for these lead times in their production schedules.

The Future of CNC Machining in China

The future looks bright for China CNC machining parts factories. With ongoing advancements in technology, such as the incorporation of AI in production processes and the exploration of sustainable practices, Chinese factories are set to become even more integral to global supply chains. The shift towards automation and smart manufacturing will only enhance efficiency and quality, solidifying their position as leaders in the industry.

Emerging Trends in CNC Machining

Several trends are shaping the future of CNC machining:

- Automation: As robots and AI become more prevalent, the efficiency of CNC machining processes will only continue to increase.

- Green Manufacturing: Factories are increasingly focusing on sustainable practices, reducing waste, and utilizing eco-friendly materials.

- Customization: There’s a growing demand for customized parts. CNC machining's flexibility allows for quick adjustments in production to meet specific client needs.

- Integration with IoT: Smart factories are on the rise, with machine-to-machine communication enhancing the efficiency and reliability of production lines.

Conclusion

In summary, China CNC machining parts factories play a crucial role in the manufacturing industry, offering unparalleled advantages in precision, efficiency, and cost-effectiveness. As these factories continue to evolve and embrace new technologies, they will remain pivotal players in the global market. For businesses looking to thrive in today’s competitive landscape, developing partnerships with these manufacturing powerhouses may well unlock new avenues for growth and innovation. The future of CNC machining in China is not just a promising prospect; it is a guaranteed reality that industries worldwide can leverage for continued success.

For more information about partnering with leading manufacturers in China, visit deepmould.net.